Quality & Innovation

The function and quality of our products

are designed to simplify lifestyles,

enhance homes, and last a lifetime.

Survey

We systematically observe

and analyze global kitchen

usage patterns and movements.

These observations yield

valuable insights crucial for

innovating new products and

enhancing existing ones.

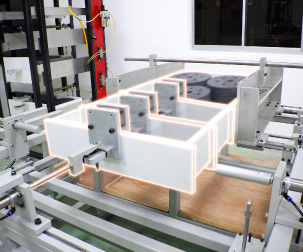

Manufacturing

Maintaining high quality standards is paramount in our product manufacturing process. Our tools and manufacturing systems undergo rigorous testing protocols consistently across all our plants.

Quality assessments and validation

Our testing procedures are

comprehensive, spanning from

the developmental phase to

production. Q-FIT’s internal

testing protocols exceed

industry standards, emphasizing

practical applications of our

products to ensure superior

quality and reliability.

Quality Control

Method

These methods provide organizations with

systematic approaches to monitor, control, and

improve their processes and products.

Statistical Process Control (SPC)

Six Sigma and Cpk

Total Productive Management (TPM)

– 5S

– Kaizen (Improvement)

– Poka Yoke (Mistake Proofing)

Six Sigma and Cpk

Total Productive Management (TPM)

– 5S

– Kaizen (Improvement)

– Poka Yoke (Mistake Proofing)

Tool

Wisely used to support implementation of quality

control practices. These tools aid in analyzing

data, identifying problems, and making informed

decisions to improve quality and efficiency.

– Quality Control Check Sheet/ Overall Equipment Efficiency (OEE)

– Fishbone Diagram / 5M & 1H

– Control Charts

– Failure Mode and Effects Analysis (FMEA)

– Fishbone Diagram / 5M & 1H

– Control Charts

– Failure Mode and Effects Analysis (FMEA)

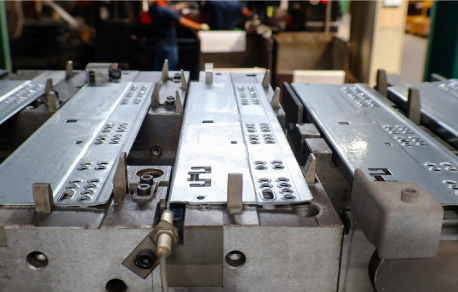

Testing Center

Under Hardware for furniture – Strength and durability of extension elements and their components

DIN EN 15338:2007-05

- Vertical downwards static overload

- Durability / Operation Forces

- Horizontal sideways static overload

- Slam Shut and Slam Open

Design Conformity

Our drawer runner systems are designed in

accordance with the principles and guidelines

specified in EN-15338-2007-05. This ensures

that our products meet the necessary ergonomic

and functional requirements for smooth operation

and reliable performance.

Material Selection

We carefully select materials for our drawer

runner systems based on the recommendations

outlined in EN-15338-2007-05. By utilizing

approved materials that meet the specified

quality standards, we guarantee the durability,

strength, and longevity of our products.

Dimensional Accuracy

Our drawer runner systems undergo meticulous

dimensional checks to verify compliance with the

dimensional tolerances specified in

EN-15338-2007-05. This ensures precise fitment

and compatibility with a wide range of cabinet

configurations and applications.

Performance Testing

Prior to market release, our drawer runner

systems undergo thorough performance testing

to validate their compliance with the performance

requirements outlined in EN-15338-2007-05.

This includes testing for load capacity, smoothness

of operation, and resistance to wear and fatigue.

Safety Compliance

We prioritize the safety of our customers, and our

drawer runner systems are engineered to meet the

safety requirements stipulated in

EN-15338-2007-05. This includes considerations

such as drawer stability, anti-tilt mechanisms, and

safety features to prevent accidental injuries or

damage.

Certified Quality

Our commitment to adhering to

EN-15338-2007-05 standards reflects our

dedication to delivering high-quality drawer

runner systems that meet the stringent

requirements of the European market. Customers

can trust in the reliability, performance, and

safety of our products, backed by our compliance

with this esteemed standard.

Quality certifications

Q-FIT’s adherence to ISO 9001 standards ensures that each Q-FIT product maintains unwavering quality.

Quality Control ensures our products meet standards under

ISO 9001:2015 fulfils customer requirements that involving

monitoring, inspecting, and corrective actions. Minimize defects,

improve customer satisfaction, enhances reliability,

optimize efficiency, and build a strong reputation.